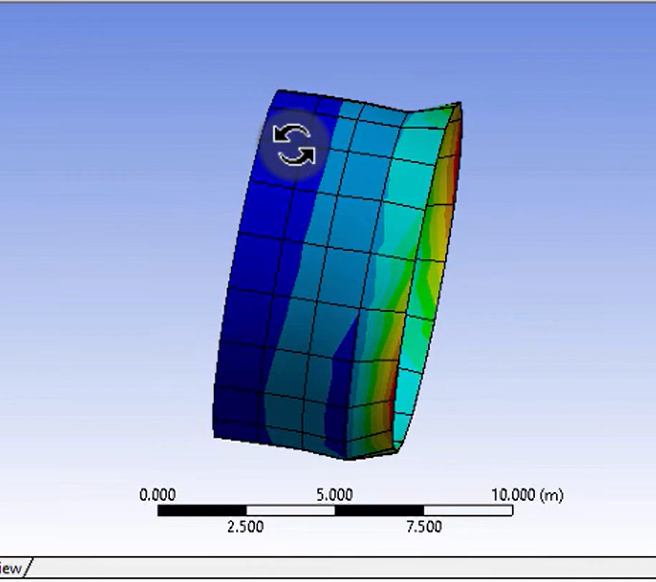

Mastering Finite Element Analysis: A Comprehensive Guide

Team EveryEng

Mechanical Engineering

FREE

208 already enrolled!

Beginner course for learners

Mastering Finite Element Analysis: A Comprehensive Guide

Trainers feedback

0

(0 reviews)

Team EveryEng

Mechanical Engineering

Course type

Watch to learn anytime

Course duration

348 Min

Course start date & time

Access anytime

Language

English

This course format through pre-recorded video. You can buy and watch it to learn at any time.

Why enroll

Unlock the power of simulation with Finite Element Method (FEM) expertise, and supercharge your career in engineering, research, and development! By mastering FEM, you'll become a sought-after professional in fields like mechanical, aerospace, civil, and biomedical engineering, with opportunities for roles like Simulation Engineer, Research Scientist, or Design Engineer. With FEM skills, you'll drive innovation, optimize designs, and solve complex problems, making you a valuable asset in industries like automotive, aerospace, and energy, and opening doors to leadership roles and entrepreneurial ventures.

Course content

The course is readily available, allowing learners to start and complete it at their own pace.

Mastering Finite Element Analysis: A Comprehensive Guide

31 Lectures

348 min

Quadratic Shape Function

12 min

Steps in FEM

8 min

Strain Displacement Matrix for Triangular element

7 min

Element Stiffness Matrix

8 min

Penalty Approach

11 min

Introduction to Shape Function

12 min

Isoparametric Formulation Numerical

4 min

Elimination Approach

15 min

Direct Stiffness matrix

11 min

2 D Finite Element Method

10 min

Weighted Residual Method

18 min

Types of Elements in Finite Element Method

11 min

Introduction of Variational Method

13 min

Global stiffness matrix

18 min

Shape function for CST element

16 min

Properties of Stiffness matrix

11 min

Stress ,Strain Relationship Matrix

10 min

Principle of Minimum Potential Energy

22 min

Galerkin Method

6 min

Advantage ,Disadvantage and Application of FEM

6 min

Gauss elimination method

8 min

Strain Displacement Matrix

7 min

Gauss Quadrature Method

8 min

Plane Stress & Plane Strain

16 min

1 D FEM for Structural Analysis

9 min

Variational method Numerical by Rayleigh Ritz Method

13 min

Shape function in Local and Natural coordinate system

17 min

Isoparametric Formulation for 1-D element

6 min

Sub Domain Method

8 min

Need of Matrix Algebra in FEM

16 min

Properties of Shape Functions

11 min

Course details

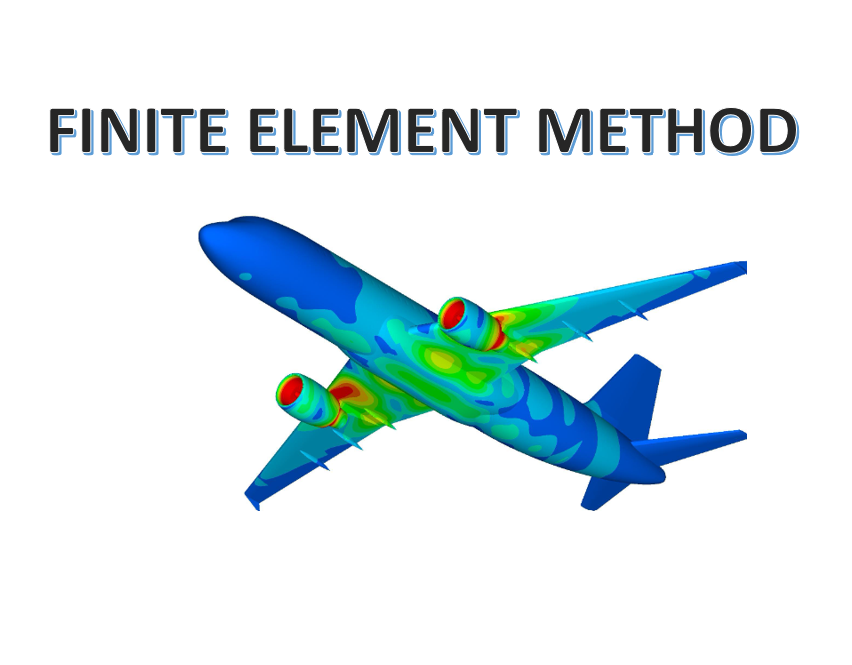

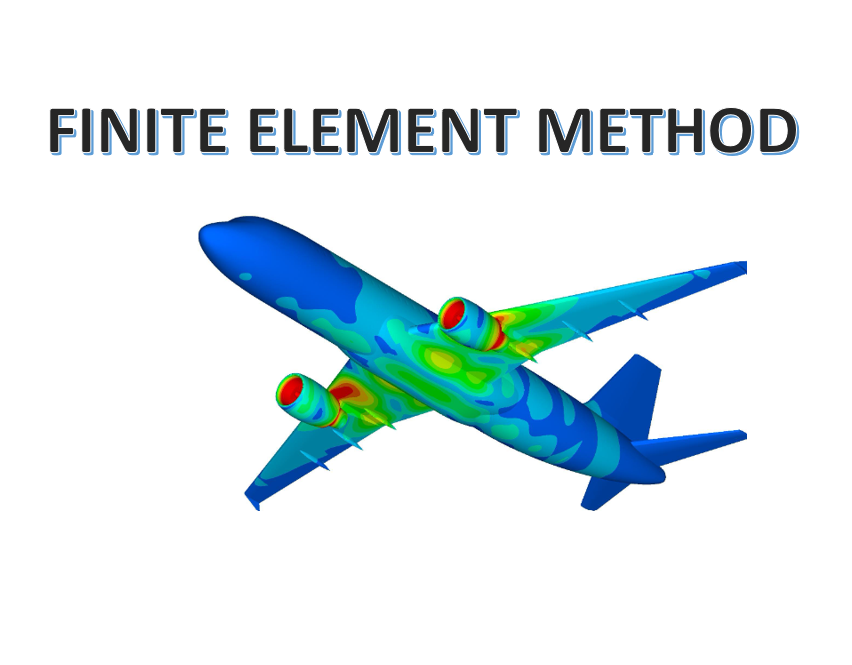

The Finite Element Method (FEM) is a powerful numerical technique used to solve partial differential equations (PDEs) governing physical phenomena across various engineering and scientific disciplines. This course provides a comprehensive introduction to the theory, implementation, and applications of the Finite Element Method. Topics covered include finite element discretization, interpolation functions, assembly of element equations, solution techniques, error estimation, and practical considerations in FEM analysis. Through theoretical lectures, hands-on programming exercises, and real-world applications, students will develop a solid understanding of FEM principles and gain proficiency in applying FEM to solve complex engineering problems.

Course suitable for

Automotive Energy & Utilities Mechanics & Turbomachinery Chemical & Process Civil & Structural Piping & Layout

Key topics covered

Types of Elements in Finite Element Method

Advantage ,Disadvantage and Application of FEM

Need of Matrix Algebra in FEM

Gauss elimination method

Direct Stiffness matrix

Global stiffness matrix

Properties of Stiffness matrix

1 D FEM for Structural Analysis

Elimination Approach

Penalty Approach

Principle of Minimum Potential Energy

Introduction to Shape Function

Shape function in Local and Natural coordinate system

Isoparametric Formulation for 1-D element

Properties of Shape Functions

Strain Displacement Matrix

Quadratic Shape Function

Steps in FEM

2 D Finite Element Method

Isoparametric Formulation Numerical

Element Stiffness Matrix

Shape function for CST element

Strain Displacement Matrix for Triangular element

Stress ,Strain Relationship Matrix

Plane Stress & Plane Strain

Gauss Quadrature Method

Weighted Residual Method

Galerkin Method

Sub Domain Method

Variational Method Introduction

Variational method Numerical by Rayleigh Ritz Method

Why people choose EveryEng

Industry-aligned courses, expert training, hands-on learning, recognized certifications, and job opportunities—all in a flexible and supportive environment.

- Industry Veteran

- Trainer Review

Team EveryEng

Mechanical Engineering

Questions and Answers

A: The main steps in setting up an FEA model are as follows: 1. Preprocessing: Define the geometry of the problem domain, select the material properties, and set boundary conditions and loads. 2. Meshing: Divide the geometry into smaller finite elements that can be analyzed; the mesh quality can significantly affect the solution accuracy. 3. Solving: Use appropriate solvers to perform numerical calculations based on the governing equations and input data. 4. Postprocessing: Interpret and visualize the results, such as stress distribution, deformation, or temperature. Each step requires careful consideration to ensure a valid and reliable simulation. A detailed guide can be found at https://nptel.ac.in/content/storage2/courses/112105265/pdf/lecture2.pdf

A: Linear finite element analysis assumes that the relationship between loads and responses is linear, meaning that deformations are small, material properties remain constant, and boundary conditions do not change during loading. This simplification allows for faster calculations but may not accurately capture real-world behaviors in many scenarios. Nonlinear finite element analysis accounts for nonlinearities that can arise from: - Material behavior (e.g., plasticity, hyperelasticity) - Large deformations or displacements - Contact problems where boundary conditions change Nonlinear FEA is more complex and computationally intensive but necessary for accurately simulating realistic responses. For an in-depth treatment, refer to https://link.springer.com/chapter/10.1007/978-3-030-23497-1_2

A: Finite Element Analysis (FEA) is a numerical method used to approximate solutions to complex engineering and physical problems. It involves breaking down a large, complex system into smaller, simpler parts called finite elements, which can be analyzed individually and then combined to approximate the behavior of the entire system. FEA is important because it allows engineers to simulate and predict how structures, materials, and components will respond to real-world forces, vibrations, heat, and other physical effects without needing to build costly prototypes. This accelerates the design process, improves safety, and reduces costs. For more detailed information, you can refer to this comprehensive overview: https://www.ansys.com/products/structures/finite-element-analysis

A: FEA can simulate heat transfer phenomena by discretizing the domain and solving thermal conduction, convection, and radiation equations. Thermal FEA can predict temperature distribution, heat fluxes, thermal stresses, and transient thermal responses in solids and fluids. Applications include thermal management of electronics, engine components, and building insulation analysis. Unlike structural FEA, input includes thermal properties like conductivity, specific heat, and convection coefficients. For an introduction to thermal FEA, check https://nptel.ac.in/content/storage2/courses/112105265/pdf/lecture10.pdf

A: Material properties define how a model responds to loads in FEA. Essential properties include elasticity modulus (Young's modulus), Poisson's ratio, density, thermal conductivity, and plasticity parameters, depending on the analysis type. Accurate input of these properties is vital; incorrect material data can lead to significant errors. Some materials exhibit nonlinear or anisotropic behavior that require advanced material models. Material property data can be obtained from handbooks, experimental testing, or manufacturers. For reference databases, visit https://www.matweb.com/

A: Choosing the appropriate mesh size is a balance between accuracy and computational cost. A finer mesh (smaller elements) generally produces more accurate results but requires more computation time and resources. Conversely, a coarse mesh reduces computational effort but may miss critical details or produce inaccurate results. The decision depends on factors such as: - The complexity of the geometry - Areas experiencing high gradients of stress or strain - The type of analysis (static, dynamic, thermal) - Required accuracy A common practice is to perform a mesh convergence study, where the mesh is progressively refined until the results converge within an acceptable tolerance. For mesh guidelines and convergence practices, see: https://www.simscale.com/docs/simwiki/mesh-convergence-study/

A: There are many commercial and open-source FEA software packages tailored to different industries and applications. Some popular commercial tools include: - ANSYS: Widely used for structural, thermal, and multiphysics simulations - Abaqus: Known for advanced nonlinear and explicit dynamic analysis - COMSOL Multiphysics: Offers coupled physics simulations - NASTRAN: Commonly used in aerospace and automotive industries Open-source tools include: - CalculiX - Elmer - Code_Aster The choice depends on budget, problem complexity, and specific features needed. More information and software comparisons can be found at https://www.engineeringclicks.com/best-finite-element-analysis-software/

A: Finite elements can be classified based on their dimensionality and shape, including: - 1D elements: Used for beams, trusses, and frames (e.g., line elements) - 2D elements: Used for shells and membranes (e.g., triangular, quadrilateral elements) - 3D elements: Used for solids (e.g., tetrahedral, hexahedral elements) The choice depends on the problem geometry and physics; for example, shell elements are efficient for thin structures while solid elements are better for 3D stress analysis. Each type also has different formulations like linear, quadratic, or higher-order elements to capture varying accuracy and computational power. More detailed descriptions can be found at https://www.autodesk.com/redshift/types-of-finite-elements/

A: Validation and verification (V&V) are critical steps to ensure the reliability of FEA results: - Verification ensures that the FEA model is implemented correctly by checking the model setup, mesh quality, solver settings, and convergence. - Validation compares simulation results to experimental data or analytical solutions to confirm the model accurately represents reality. Common methods include mesh refinement studies, comparing stress or displacement results to known benchmarks, and performing physical testing. Documentation on best practices for V&V can be found here: https://www.nist.gov/publications/guide-verification-and-validation-computational-models

A: Boundary conditions (BCs) are essential for defining how a model interacts with its environment, including constraints (fixed supports, symmetry) and applied loads (forces, pressures, temperature). Incorrectly applied or unrealistic BCs can lead to inaccurate or non-physical results such as zero displacement where movement should occur or illogical stress concentrations. Proper BCs ensure that the model is stable and mimics actual operating conditions. It’s important to carefully interpret the physical situation and apply BCs accordingly. For guidelines on setting BCs, see https://www.caelinux.com/CMS/index.php?option=com_content&view=article&id=121&Itemid=170

More from Same Author

- Technical Courses

- Articles

1928

67

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

1237

15

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

489

9

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

Earning and Growth option in same Industry Domain

- Pre-recorded

- Online live session

- Offline

- Articles

5102

150

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

3128

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

753

1

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

More Training & Development option to expand your reach

- Technical courses

- Soft-skills courses

- Seminars

- Articles & Blogs

757

2

Online

Live courses

November 16

30 Hrs

Advanced

Online

Live courses

Interacting with trainer

166

Online

Live courses

December 27

30 Hrs

Advanced

Online

Live courses

Interacting with trainer

409

Online

Live courses

January 24

45 Hrs

Advanced

Online

Live courses

Interacting with trainer