A Complete Course on NDT Training I & II

Chaitanya Purohit

Consultant

COMPLETED

Advanced course for professionals

A Complete Course on NDT Training I & II

Trainers feedback

0

(0 reviews)

Chaitanya Purohit

Consultant

Course type

Instructor led live training

Course duration

60 Hrs

Course start date & time

April 12, 2025 | 01:31 PM

Language

English

This course format is where trainer will explain you the subject via online live session. This course will run as per specific date and time.

Why enroll

Professionals are drawn to NDT (non-destructive testing) training courses because they want to acquire the skills to detect defects and flaws in materials, components, and systems without causing damage. By learning NDT techniques, they can ensure the safety and quality of products, prevent costly repairs, and reduce the risk of accidents. This expertise is highly valued in industries such as aerospace, oil and gas, and construction, making NDT training a valuable investment for career advancement.

Course details

With current industry growth rate, keeping Safety and Quality prime value drivers, scope of NDT increased in a big way. Industry is in need of competent personnel to evaluate material, component, assembly, equipment using various NDT Techniques to ensure the integrity and reliability.

As time elapsed, plants and refineries susceptible to wear or worn out. Hence, it is necessary to conduct in-service inspection to examine plant structures, equipment and components to detect and identify possible deterioration as a part of predictive maintenance.

NDT is very much helpful to make decision whether to continue the equipment / component in service to maintain asset integrity, availability and reliability of the Plant

To cater the need of the industry we developed NDT Level-I and Level-II training and Certification program for organisations and individuals in their respective sector of industry.

We also provide tailored training and refresher programs for Organisations at their premises. For working professionals evening and weekend programs are available.

As a career field, non-destructive testing offers many opportunities, and there is a big demand for technicians and engineers proficient in NDT.

Course Detail :

Program developed based on the Guidelines from American Society of Non-Destructive Testing

Upon completion of Training you will be awarded the Attendance Certificate.

Composite Examination containing General , Specific and Practical to be cleared by each candidate (70% in individual examination and 80% aggregate as described in SNT-TC-1A for qualification), to receive Certification.

Why Q-Tech

Program director is Metallurgist having in-depth knowledge and rich hands on experience in Welding, Manufacturing processes, Fabrication, NDT, Inspection and Quality Control. He is aware of the need of the different industries as he worked in India, south east Asia and middle east for Oil & Gas companies, Refineries, Heavy Engineering and manufacturing industries, EPC companies and dealt with most of the oil and gas giant worldwide. During the course you will get benefitted with his real examples and global experience.

Along with NDT, participants will also learn basics of Material, its properties, Manufacturing processes, Welding processes in brief which will enhance their performance and contributing in career building.

Program also covers industrial visits and hands on for the candidates to have feel of application.

Level of Qualification :

NDT Level-I : Individual qualified to properly perform calibration, specific NDT, and specific evaluation for acceptance or rejection determination according to written instruction and shall be capable to record results.

NDT Level-I shall receive the instruction from Level-II or Level-III.

NDT Level-II : Individual qualified to set up and calibrate equipment, interpret and evaluate the results with respect to applicable code and standards. Thoroughly familiar with the scope and limitation of the method in which he/she qualified. Provide on-job training and guidance to Trainee and NDT Level-I

Course suitable for

Aerospace Energy & Utilities Metallurgy & Material Science

Key topics covered

Training details

This is a live course that has a scheduled start date.

Live session

April 12, 2025 | 01:31 PM

2 Hours every day

30 Days

Why people choose EveryEng

Industry-aligned courses, expert training, hands-on learning, recognized certifications, and job opportunities—all in a flexible and supportive environment.

- Industry Veteran

- Trainer Review

COMPLETED

April 12, 2025

Questions and Answers

A: Magnetic Particle Testing (MT) is applicable only to ferromagnetic materials and detects surface and near-surface discontinuities by applying a magnetic field and sprinkling iron particles that cluster at leakage fields caused by defects. Liquid Penetrant Testing (PT), on the other hand, is suitable for almost all non-porous materials and involves applying a liquid dye that seeps into surface cracks, which becomes visible under ultraviolet or white light after developer application. MT often requires magnetization equipment but provides quick detection, while PT is simpler but only detects surface-breaking defects. Both methods are complementary in inspection strategies. More details at: https://www.twi-global.com/technical-knowledge/faqs/faq-what-is-magnetic-particle-testing-and-liquid-penetrant-testing

A: NDT technicians typically need certifications based on standards such as ASNT SNT-TC-1A, ISO 9712, or EN 4179 depending on the industry and country. Certifications are divided by method and level (Level I, II, III), with Level I being entry-level technicians, Level II qualified to set up equipment and interpret results, and Level III capable of developing procedures and managing NDT programs. Training involves theoretical knowledge, practical hands-on experience, and passing exams. Continual certification renewals ensure skills remain current. More about certifications can be found here: https://www.asnt.org/MajorSiteSections/Certification/Overview

A: Radiographic Testing (RT) involves ionizing radiation (X-rays or gamma rays), which can be hazardous to health. Essential safety precautions include: using shielding like lead barriers, maintaining a safe distance from the source, employing proper personal protective equipment (PPE), ensuring only trained and authorized personnel operate the equipment, conducting radiation surveys, and following regulatory limits for exposure. Always adhere to institutional and national radiation safety protocols. For comprehensive safety guidelines, visit: https://www.epa.gov/radiation/radiation-safety-guidance

A: Calibration in NDT ensures that equipment and techniques produce accurate, reliable data. It involves comparing the instrument's measurements against known standards or reference materials with predefined properties or defects. This process is critical for defect size estimation, material thickness evaluations, and overall inspection validity. Calibration frequency depends on equipment use and regulatory requirements. For example, ultrasonic flaw detectors are calibrated with reference blocks containing artificial reflectors. Proper documentation and adherence to standards like ISO 17025 are necessary. Learn more at: https://www.nde-ed.org/EducationResources/CommunityCollege/BasicNDT/calibration/calibration.htm

A: The main NDT methods include Visual Testing (VT), Ultrasonic Testing (UT), Radiographic Testing (RT), Magnetic Particle Testing (MT), Liquid Penetrant Testing (PT), Eddy Current Testing (ET), and Acoustic Emission Testing (AE). Visual Testing is used for surface inspections, Ultrasonic Testing uses sound waves for thickness and flaw detection, Radiographic Testing employs X-rays to view internal structures, Magnetic Particle Testing detects surface and near-surface defects in ferromagnetic materials, Liquid Penetrant Testing reveals cracks on non-porous surfaces, Eddy Current Testing is used for conductive materials mainly to detect surface cracks, and Acoustic Emission Testing monitors the sound waves from cracks or defects during stress. Each method is selected based on material type, defect nature, and inspection conditions. Refer to ASNT’s overview: https://www.asnt.org/MinorSiteSections/NDT-Methods

A: Non-Destructive Testing (NDT) refers to a range of analysis techniques used in science and industry to evaluate the properties of a material, component, or system without causing damage. Its importance lies in the ability to detect defects and ensure safety, reliability, and integrity without impairing the part's future usability. NDT is vital in sectors like aerospace, automotive, and construction to prevent failures and reduce costs. For more information, you can visit: https://www.nist.gov/topics/non-destructive-evaluation

A: There are many reputable sources offering comprehensive NDT training and resources including the American Society for Nondestructive Testing (ASNT) which provides certifications, courses, and technical resources. The British Institute of Non-Destructive Testing (BINDT) also offers extensive training programs and publications. Additionally, websites like NDT.net provide forums, technical papers, and updates on NDT technology. Universities and technical colleges may offer diploma or degree programs. You can explore: https://www.asnt.org/, https://www.bindt.org/, and https://www.ndt.net/ for further learning.

A: Eddy Current Testing (ET) uses electromagnetic induction to detect flaws in conductive materials. An alternating current in a coil generates a changing magnetic field, inducing eddy currents in the test object. Discontinuities or changes in material properties alter these currents, which are detected by changes in coil impedance. ET is widely used for surface crack detection, conductivity measurement, and thickness gauging, especially in aerospace, power generation, and tubing inspections. It is fast and requires minimal surface preparation. For more details, see: https://www.ndt.net/article/v06n03/maue/maue.htm

A: Environmental factors such as temperature extremes, humidity, surface contamination, electromagnetic interference, and lighting conditions can all impact NDT accuracy. For instance, high temperatures can alter material properties or affect equipment performance, moisture can affect dye penetrant inspections, and bright sunlight can interfere with fluorescent penetrant reading. Mitigation includes controlling inspection environment, using proper surface cleaning, choosing suitable methods for conditions, employing shielding from interferences, and using standardized procedures. Thorough preparation and understanding of site conditions help ensure consistent results.

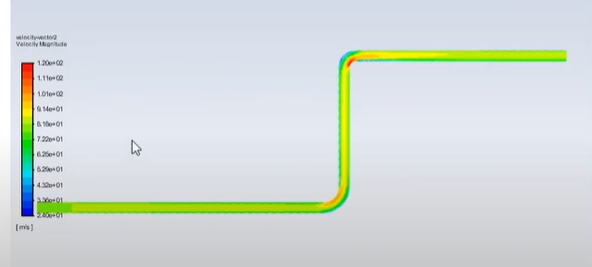

A: Ultrasonic Testing (UT) works by sending high-frequency sound waves into a material. When these waves encounter a boundary like a crack or inclusion, they reflect back and are detected by a transducer. The time and amplitude of these echoes help determine the location and size of defects. Challenges in UT include surface roughness affecting coupling, complex geometries causing signal distortions, operator skill for proper interpretation, and material attenuation that can reduce signal strength. Proper calibration and experience help mitigate these issues. Detailed insights can be found at: https://www.nde-ed.org/EducationResources/CommunityCollege/Ultrasonics/Introduction/ut_intro.htm

More from Same Author

- Technical Courses

- Articles

407

Online

Live courses

Beginner

Online

Live courses

Interacting with trainer

396

Online

Live courses

Beginner

Online

Live courses

Interacting with trainer

361

Online

Live courses

Beginner

Online

Live courses

Interacting with trainer

Earning and Growth option in same Industry Domain

- Pre-recorded

- Online live session

- Offline

- Articles

665

15

E-Learning

Unlimited access

Beginner

E-Learning

Unlimited access

Pre-recorded videos

1284

2

E-Learning

Unlimited access

Beginner

E-Learning

Unlimited access

Pre-recorded videos

729

E-Learning

Unlimited access

Beginner

E-Learning

Unlimited access

Pre-recorded videos

More Training & Development option to expand your reach

- Technical courses

- Soft-skills courses

- Seminars

- Articles & Blogs

302

Online

Live courses

December 27

30 Hrs

Advanced

Online

Live courses

Interacting with trainer

541

Online

Live courses

January 24

45 Hrs

Advanced

Online

Live courses

Interacting with trainer

245

Online

Live courses

February 21

30 Hrs

Advanced

Online

Live courses

Interacting with trainer