Mud School - Drilling Fluid Course

Dr Milap Goud

Founder and Instructor

$ 1200

Advanced course for professionals

Mud School - Drilling Fluid Course

Trainers feedback

0

(0 reviews)

Dr Milap Goud

Founder and Instructor

Course type

Instructor led live training

Course duration

30 Hrs

Course start date & time

Coming in Next Month

Language

English

This course format is where trainer will explain you the subject via online live session. Date and time are not decided yet but it will be planned within next 2 weeks after you enroll & pay for this course?. Get in touch with our team if any clarification is required.

Course details

Course Duration- 30 hrs

Post Training test will be conducted by mentor, candidates need to score above 80%

Learning Objective:

Upon completion of the course, participants will be able to:

· Acquire a thorough knowledge of drilling fluids and rheology,

· Learn how to choose the right equipment for solid removal,

· Learn how to design a Mud System.

Course Content:

Basic introduction with brief description about history and stagewise development to meet challenges of drilling

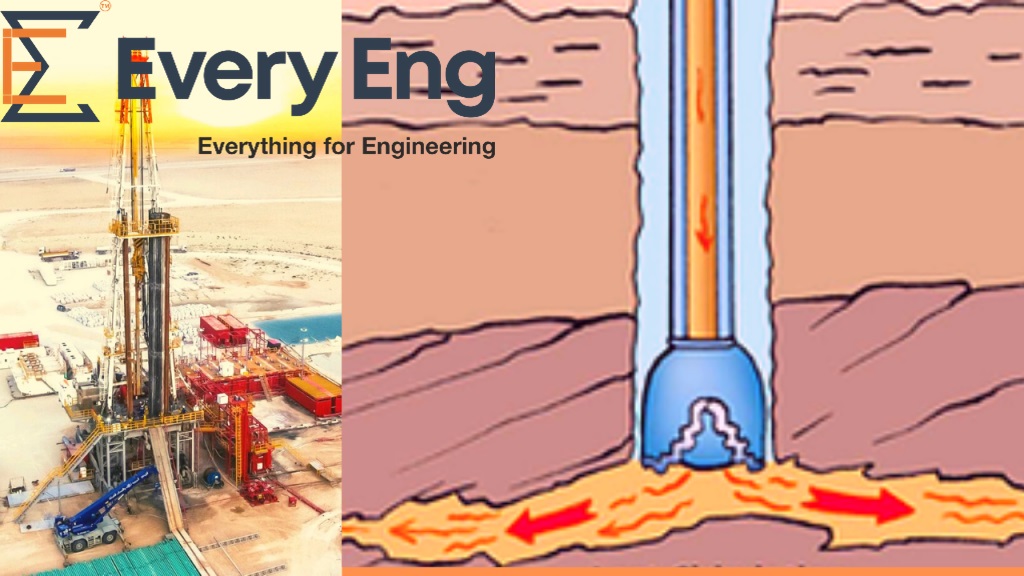

Definition, functions of mud and how it helps in drilling

Properties of mud, their relevance and role in various segments of drilling

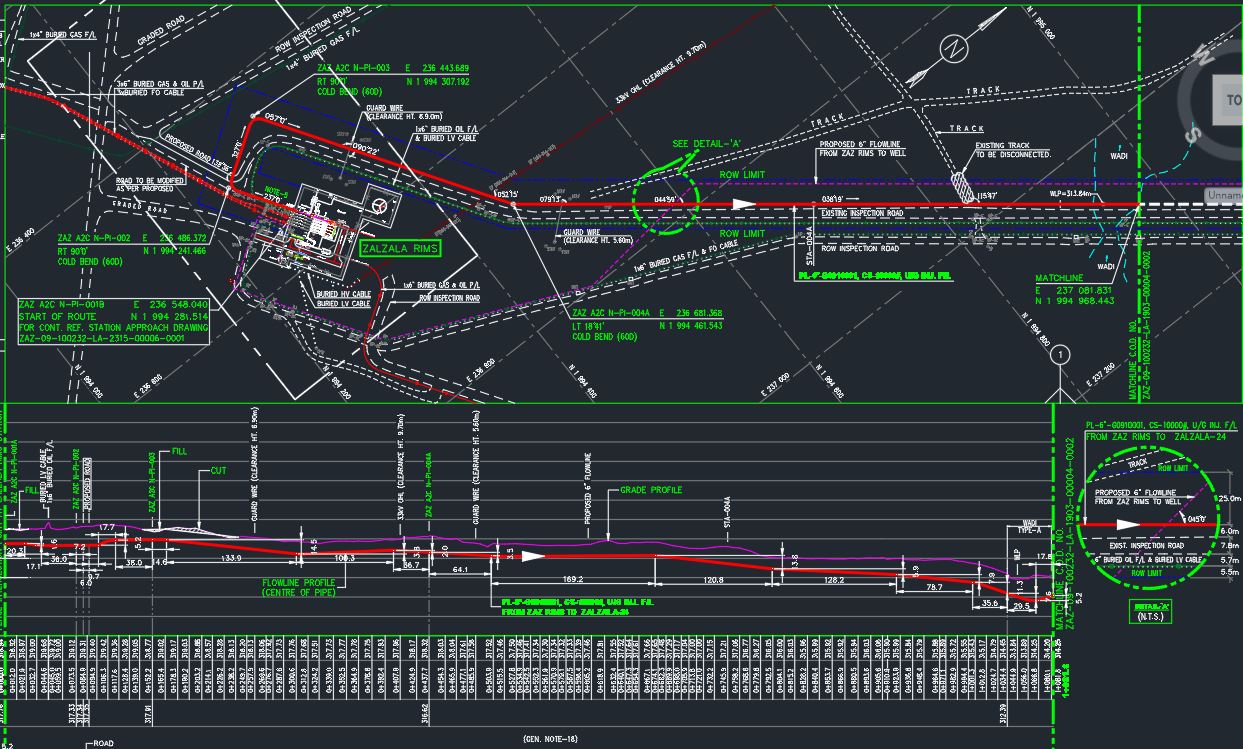

Brief description of geo-mechanical modelling with respect to drilling fluids and drilling engineering for effective well design

Introduction to Rheology and hydraulics with explanation of their importance in drilling and how drilling fluid will help in effective management of rheology and hydraulics

Mud Chemicals, various categories with examples, generic structure and mechanism of action to impart the properties in chosen range

Types of mud systems, a brief overview

Fresh water low solids system

PHB/CMC/LIGNITE system

K Cl/PHPA/GLYCOL/Polymer mud system

Solids free heavy density drilling fluids

High performance water based mud

Reservoir drill-in fluids with exposure to formation damage and role of mud to protect the formation from possible damage

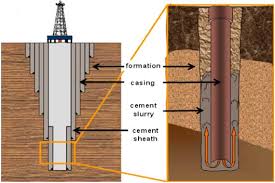

Well-bore integrity management

Non-aqueous mud -introduction, why non-aqueous mud is required

Details of formulation with explanation on each merit

comparing water and oil base mud for selecting correct mud system with respect to the type of rock

Various complications related to drilling management and role of mud in mitigating them

Solids management

Deep-water drilling fluids

HTHP drilling fluids

Surfactants and their role in drilling fluids management

Practical tips to manage/condition mud on rig while working as a mud engineer

Completion fluids

Case histories discussion

Basic drilling fluids calculations

Contamination management

Course suitable for

Oil & Gas Petroleum Geoscience

Key topics covered

Key Topics covered:

Basic introduction with brief description about history and stagewise development to meet challenges of drilling

Definition, functions of mud and how it helps in drilling

Properties of mud, their relevance and role in various segments of drilling

Brief description of geo-mechanical modelling with respect to drilling fluids and drilling engineering for effective well design

Introduction to Rheology and hydraulics with explanation of their importance in drilling and how drilling fluid will help in effective management of rheology and hydraulics

Mud Chemicals, various categories with examples, generic structure and mechanism of action to impart the properties in chosen range

Types of mud systems, a brief overview

Fresh water low solids system

PHB/CMC/LIGNITE system

K Cl/PHPA/GLYCOL/Polymer mud system

Solids free heavy density drilling fluids

High performance water based mud

Reservoir drill-in fluids with exposure to formation damage and role of mud to protect the formation from possible damage

Well-bore integrity management

Non-aqueous mud -introduction, why non-aqueous mud is required

Details of formulation with explanation on each merit

comparing water and oil base mud for selecting correct mud system with respect to the type of rock

Various complications related to drilling management and role of mud in mitigating them

Solids management

Deep-water drilling fluids

HTHP drilling fluids

Surfactants and their role in drilling fluids management

Practical tips to manage/condition mud on rig while working as a mud engineer

Completion fluids

Case histories discussion

Basic drilling fluids calculations

Contamination management

Training details

This is a live course that has a scheduled start date.

Live session

Why people choose EveryEng

Industry-aligned courses, expert training, hands-on learning, recognized certifications, and job opportunities—all in a flexible and supportive environment.

- Industry Veteran

- Trainer Review

$ 1200

- $ 0 Early bird discount

Coming in Next Month

Questions and Answers

A: Key properties include density, viscosity, pH, filtrate loss, and solids content. Density is measured using a mud balance. Viscosity is assessed with a Marsh funnel or rheometer to understand the flow behavior of the fluid. pH is measured with a standard pH meter and is important because it affects the stability of additives. Filtrate loss, measured by API filter press tests, indicates the fluid’s tendency to invade formations. Solids content is measured with a retort test or centrifuge. These tests ensure the fluid is functioning properly and can be adjusted as needed. Comprehensive testing procedures are outlined in the API Recommended Practice 13B: https://www.api.org/products-and-services/standards.

A: Drilling fluid density is primarily controlled by adding weighting materials like barite or hematite to the base fluid. The density must be carefully managed to provide enough hydrostatic pressure to balance formation pressures and prevent kicks or blowouts without fracturing the formation. If the density is too low, formation fluids may enter the wellbore (a kick), and if too high, it can fracture the formation leading to lost circulation. Tools like mud balances are used to measure density at the rig. For an in-depth explanation, you might visit Schlumberger's Oilfield Glossary: https://www.glossary.oilfield.slb.com/.

A: The primary types of drilling fluids are: 1) Water-Based Mud (WBM) - These use water as the continuous phase with various additives to improve properties. They are cost-effective and environmentally friendly but may have limitations in challenging formations. 2) Oil-Based Mud (OBM) - These use oil as the continuous phase and provide excellent lubrication and shale inhibition but are more expensive and have environmental restrictions. 3) Synthetic-Based Mud (SBM) - Similar to OBM but use synthetic oils, which reduce environmental impact. Each type offers advantages and disadvantages depending on the drilling conditions. Detailed comparisons can be found in the API (American Petroleum Institute) drilling fluid guidelines: https://www.api.org/.

A: Environmental considerations include the toxicity, biodegradability, and disposal methods of the drilling fluid. Water-based muds are generally preferred for environmental sensitivity but may not perform well in all conditions. Oil-based and synthetic-based muds require special handling and disposal because of potential toxicity and contamination risks. Regulations vary by region, and operators must comply with local environmental laws such as the EPA regulations in the United States. For guidelines on environmental aspects of drilling fluids, see the International Association of Drilling Contractors (IADC) environmental handbook: https://www.iadc.org/.

A: Drilling fluids, also known as drilling muds, serve several essential functions in the drilling process. These include: 1) Removing cuttings from the wellbore to the surface 2) Cooling and lubricating the drill bit 3) Controlling formation pressures to prevent blowouts by providing hydrostatic pressure 4) Stabilizing the wellbore walls to avoid collapse 5) Transmitting hydraulic energy to the drill bit 6) Minimizing formation damage by controlling fluid invasion. For more detailed information, you can refer to the Society of Petroleum Engineers' resources on drilling fluids: https://www.spe.org/en/.

More from Same Author

- Technical Courses

- Articles

2027

2

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

902

Online

Live courses

Online

Live courses

Interacting with trainer

652

1

Online

Live courses

Online

Live courses

Interacting with trainer

Earning and Growth option in same Industry Domain

- Pre-recorded

- Online live session

- Offline

- Articles

2034

2

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

7613

387

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

4418

6

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

More Training & Development option to expand your reach

- Technical courses

- Soft-skills courses

- Seminars

- Articles & Blogs

757

2

Online

Live courses

November 16

30 Hrs

Advanced

Online

Live courses

Interacting with trainer

166

Online

Live courses

December 27

30 Hrs

Advanced

Online

Live courses

Interacting with trainer

409

Online

Live courses

January 24

45 Hrs

Advanced

Online

Live courses

Interacting with trainer