Casting

Trainers feedback

0

(0 reviews)

Team EveryEng

Mechanical Engineering

Course type

Watch to learn anytime

Course duration

492 Min

Course start date & time

Access anytime

Language

English

This course format through pre-recorded video. You can buy and watch it to learn at any time.

Why enroll

Unlock the secrets of casting and transform your manufacturing skills! Our comprehensive casting course covers the fundamentals of sand casting, investment casting, die casting, and more. Learn from industry experts and master the techniques to produce high-quality castings with precision and accuracy. Ideal for foundry professionals, engineers, and manufacturers, this course will enhance your knowledge, improve productivity, and boost your career prospects.

Enroll now and:

- Master casting processes and techniques

- Improve product quality and reduce defects

- Increase efficiency and productivity

- Stay competitive in the industry

Course content

The course is readily available, allowing learners to start and complete it at their own pace.

Casting

15 Lectures

492 min

Steps of Casting Processes

26 min

Casting: Terminology

40 min

The Pattern Allowances I

34 min

The Pattern Allowances II

31 min

Casting: Sand Moulding l

31 min

Sand Moulding II

38 min

Casting: Core and Core Prints

36 min

Casting: Gating System

39 min

Casting: Yield and Riser Design

31 min

Casting: Riser Design

25 min

Casting: Cleaning of Castings

30 min

Casting Casting Defects and their Preventions

42 min

Metal Working Processes: Hot & Cold Working

32 min

Casting: Shell Mould Casting

29 min

Casting: Investment and Permanent Mould Casting

28 min

Course details

Casting is a manufacturing process that involves pouring molten metal into a mold to create a desired shape or design. This ancient technique has been refined over centuries and is widely used in various industries, including aerospace, automotive, medical, and industrial applications. The casting process begins with creating a pattern or replica of the desired shape, followed by preparing the mold cavity. The molten metal is then poured into the mold, allowed to solidify, and removed once cooled. The resulting product, called a casting, can be made from a range of materials, including ferrous and non-ferrous metals, superalloys, and composites.

The versatility of casting lies in its ability to produce complex geometries and intricate designs, making it an ideal method for creating components such as engine blocks, cylinder heads, gearboxes, and turbine blades. Additionally, casting enables high-volume production through techniques like die casting and continuous casting. However, casting also presents challenges, including material limitations, defects, dimensional accuracy, and surface finish. To overcome these issues, foundries employ various techniques, such as gravity casting, pressure casting, vacuum casting, and squeeze casting.

The benefits of casting are numerous, including cost-effectiveness, reduced machining and assembly costs, and the ability to produce complex shapes. Casting also allows for material versatility, enabling the use of various metals and alloys. With advancements in technology and simulation software, casting has become increasingly precise, enabling the production of high-quality components with improved mechanical properties. As a result, casting remains a vital manufacturing process, driving innovation and productivity across diverse industries.

Course suitable for

Manufacturing Mechanical Production

Key topics covered

Why people choose EveryEng

Industry-aligned courses, expert training, hands-on learning, recognized certifications, and job opportunities—all in a flexible and supportive environment.

- Industry Veteran

- Trainer Review

Team EveryEng

Mechanical Engineering

Questions and Answers

A: Common metals used in casting include cast iron, aluminum, steel, copper alloys, magnesium, and zinc. The selection depends on factors such as mechanical properties required, corrosion resistance, melting point, fluidity, cost, and specific application needs. For instance, aluminum is lightweight with good corrosion resistance and is used extensively in automotive parts, while cast iron offers excellent wear resistance and is common in heavy machinery. The choice also depends on casting method compatibility and post-processing requirements. For comparative information, see https://www.metallurgicalcasting.com/metal-selection-guide

A: Gating and riser systems are critical for controlling the flow of molten metal into the mold and ensuring proper feeding during solidification. Well-designed gating minimizes turbulence, which reduces the risk of defects like porosity and inclusions. Risers act as reservoirs of molten metal that compensate for shrinkage during solidification, preventing voids and ensuring sound castings. Improper design can lead to defects, increased scrap rates, and poor mechanical properties. Factors like gating size, shape, location, and riser volume must be optimized based on casting geometry and alloy properties. Detailed design guidelines can be found at https://www.foundrymag.com/designing-gates-and-risers-casting-quality

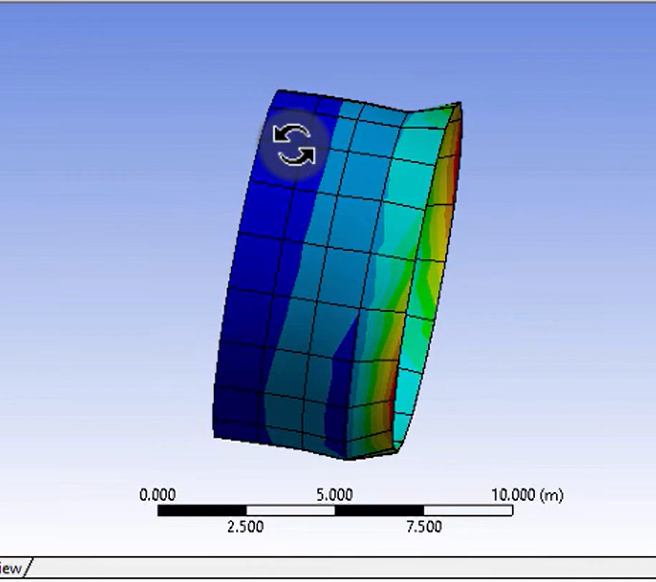

A: Simulation software allows engineers to model and analyze the casting process virtually before manufacturing. It helps predict issues such as flow behavior, solidification patterns, stress distribution, and potential defects like porosity and shrinkage. This enables optimization of gating and riser design, mold temperature control, and alloy selection, reducing trial-and-error, saving time, and lowering production costs. Widely used tools include MAGMASOFT, ProCAST, and FLOW-3D Cast. Utilizing simulation enhances casting quality and efficiency significantly. Explore more about casting simulation at https://www.simu-casting.com/

A: The mold material significantly influences the cooling rate, surface finish, dimensional accuracy, and the types of alloys that can be cast. For example, sand molds are inexpensive and adaptable but have lower dimensional precision and surface finish compared to permanent molds made from metal. Permanent molds allow for faster production and better surface quality but are costlier and limited to certain metals. Additionally, refractory and ceramic molds can withstand higher temperatures and are useful for casting reactive metals. The thermal conductivity, strength, and permeability of the mold material must match the requirements of the casting process and material being cast. More information is available at https://www.processmaterials.com/casting-mold-materials/

A: Casting processes can have several environmental impacts, including emissions of harmful gases, consumption of energy, generation of waste materials like used sand and slag, and water pollution from cooling and cleaning operations. To mitigate these, the industry is adopting greener approaches such as recycling and reclaiming sand molds, using cleaner energy sources, implementing stricter emission controls, and developing more environmentally friendly binders and coatings for molds. Advances in process efficiency and the use of simulation software also help reduce material waste. Organizations such as the American Foundry Society offer guidelines on sustainable casting practices: https://www.afsinc.org/GreenCasting

A: Common casting defects include: 1) Porosity: Caused by trapped gases or shrinkage; prevented by proper venting and controlling cooling rates. 2) Cold shuts: Occur when two metal streams do not fuse properly; prevented by proper gating design and maintaining pouring temperature. 3) Inclusion: Non-metallic materials get trapped inside; avoided by using clean raw materials and proper melting practices. 4) Misruns: Incomplete filling of the mold due to premature solidification; prevented by maintaining correct pouring temperatures and gating system design. 5) Hot tearing: Cracks formed during solidification due to stresses; minimized by using appropriate alloy compositions and mold design. For detailed strategies, see https://www.metalcastingdesign.com/casting-defects.html

A: The main types of casting processes include: 1) Sand Casting: Uses sand as the mold material; versatile and widely used. 2) Die Casting: Involves forcing molten metal into a mold cavity under high pressure; suitable for high-volume production. 3) Investment Casting: Also known as lost-wax casting; offers excellent surface finish and precision. 4) Centrifugal Casting: Uses centrifugal force to distribute molten metal in the mold; commonly used for cylindrical parts. 5) Continuous Casting: Used for producing long lengths of metal sections like rods or sheets. Each process has specific applications depending on the material, desired properties, and production volume. Visit https://www.azom.com/article.aspx?ArticleID=5601 for an in-depth overview.

A: Casting is a manufacturing process in which a liquid material, usually metal, is poured into a mold that contains a hollow cavity of the desired shape and then allowed to solidify. Once solidified, the casting is removed from the mold to undergo further finishing. Casting is important because it allows for the creation of complex shapes that would be difficult or uneconomical to make by other methods. It is widely used in various industries such as automotive, aerospace, and machinery to produce components with a high degree of precision and repeatability. For more details, you can refer to: https://www.sciencedirect.com/topics/engineering/casting

A: Quality control in casting involves monitoring raw materials, melting and pouring parameters, mold quality, and process conditions consistently. Inspections include visual checks, dimensional measurements, and non-destructive testing like radiography and ultrasonic testing to detect internal flaws. Statistical process control helps maintain process consistency. Implementing standards such as ASTM or ISO ensures uniformity. Documentation, operator training, and traceability are also important parts of quality management. More guidelines can be found at https://www.qualitymag.com/articles/93081-casting-quality-control-techniques

A: Post-casting processes include fettling (removing gates, risers, and excess material), heat treatment to improve mechanical properties, surface finishing (grinding, polishing, shot blasting), machining for dimensional accuracy, and non-destructive testing (X-ray, ultrasonic) to detect internal defects. These steps ensure the casting meets the required specifications and performance criteria. Heat treatment can relieve stresses and enhance hardness or ductility, while machining is critical for precision components. For an overview, visit https://www.castinginspection.org/post-casting-operations/

More from Same Author

- Technical Courses

- Articles

1928

67

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

1237

15

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

489

9

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

Earning and Growth option in same Industry Domain

- Pre-recorded

- Online live session

- Offline

- Articles

987

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

1118

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

822

E-Learning

Unlimited access

E-Learning

Unlimited access

Pre-recorded videos

More Training & Development option to expand your reach

- Technical courses

- Soft-skills courses

- Seminars

- Articles & Blogs

757

2

Online

Live courses

November 16

30 Hrs

Advanced

Online

Live courses

Interacting with trainer

166

Online

Live courses

December 27

30 Hrs

Advanced

Online

Live courses

Interacting with trainer

409

Online

Live courses

January 24

45 Hrs

Advanced

Online

Live courses

Interacting with trainer