An Overview of Drilling Fluid Technology

Dr Milap Goud

Founder and Instructor

COMPLETED

38 already enrolled!

Basic course for beginners

Anytime Learning

Learn from Industry Expert

Career Option Guideline

An Overview of Drilling Fluid Technology

Trainers feedback

0

(0 reviews)

Dr Milap Goud

Founder and Instructor

Course type

Instructor led live training

Course duration

1 Hrs

Course start date & time

October 5, 2024 | 06:00 AM

Language

English

This course format is where trainer will explain you the subject via online live session. This course will run as per specific date and time.

Why enroll

This course will give insight of all applications and importance of drilling fluid technology and an overview of future courses to be delivered by instructor.

Its useful for

Drilling engineers and fluid specialists.

Geologists and geoscientists involved in well planning and execution.

Environmental engineers focused on oil and gas.

Researchers and innovators in fluid technology.

Top of Form

Course details

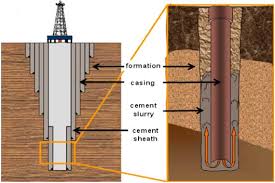

A Drilling Fluid Technology Course typically covers the latest advancements, trends, and fundamentals in the field of drilling fluids, also known as drilling mud. These fluids play a critical role in the oil and gas industry, facilitating the drilling process by cooling and lubricating the drill bit, stabilizing the wellbore, and carrying cuttings to the surface.

Useful for,

Drilling engineers and fluid specialists.

Geologists and geoscientists involved in well planning and execution.

Environmental engineers focused on oil and gas.

Researchers and innovators in fluid technology.

Description :

1. Brief overview of Drilling fluid Technology:

The topics covered will be importance of Drilling fluids, Types, composition, properties, rheology, Functions of drilling fluids, wellbore stability, Environmental impacts of drilling fluids, regulatory requirements for drilling fluid measurement, new developments in drilling fluid formulation, challenges and solutions in drilling fluid management, innovation in mud monitoring and automation technologies, case studies and practical applications, future trends in drilling fluids

2. Brief talk on future e -learning courses to be conducted by an instructor on Everyeng on various topics such with course name and duration of the course:

· IADC approved course on Drilling fluids- 30 hrs

· Mud school course without IADC certificate- 30 hrs

· IADC approved course on cement slurry design-24 hr

· Cement slurry design course without IADC certificate-24 hr

· Nanotechnology, an overview with focus on E and P operations-8 hr

· Wellbore integrity management- 8hr

· Natural gas hydrates- An overview- 8 hr

· E and P contract management- 16 hr

Top of Form

Course suitable for

Oil & Gas Geoscience Petroleum

Key topics covered

Key Topics Covered:

Introduction to Drilling Fluids:

Overview of the role and importance of drilling fluids.

Types of drilling fluids: Water-based, Oil-based, and Synthetic-based muds.

Composition and properties of drilling fluids.

Rheology and Flow Characteristics:

Understanding the flow behaviour of drilling fluids.

Rheological models and their application in real-time drilling operations.

Functions of Drilling Fluids:

Wellbore stability.

Formation pressure control.

Lubrication and cooling of the drill bit.

Cuttings transportation and hole cleaning.

Fluid Loss and Wellbore Stability:

Techniques for managing fluid loss.

Maintaining wellbore stability under various conditions.

Environmental Considerations:

Environmental impacts of different drilling fluids.

Disposal and recycling of drilling fluids.

Regulatory requirements for drilling fluid management.

New Developments in Drilling Fluid Formulation:

Nanotechnology in drilling fluids.

Biodegradable and eco-friendly fluids.

Smart fluids with enhanced real-time adaptability.

Challenges and Solutions in Drilling Fluid Management:

Mitigating common challenges like gas kicks, lost circulation, and differential sticking.

Innovations in mud monitoring and automation technologies.

Case Studies and Practical Applications:

Examples of successful drilling projects where advanced drilling fluid technologies were applied.

Failures and lessons learned.

Future Trends in Drilling Fluids:

Automation and AI in fluid management.

Evolving standards and compliance requirements.

Sustainable practices and reducing the carbon footprint in fluid production and use.

10. Brief talk on future e -learning courses to be conducted by an instructor on Everyeng on various topics with course name and duration of the course:

· IADC approved course on Drilling fluids- 30 hrs

· Mud school course without IADC certificate- 30 hrs

· IADC approved course on cement slurry design-24 hr

· Cement slurry design course without IADC certificate-24 hr

· Nanotechnology, an overview with focus on E and P operations-8 hr

· Wellbore integrity management- 8hr

· Natural gas hydrates- An overview- 8 hr

· E and P contract management- 16 hr

Training details

This is a live course that has a scheduled start date.

Live session

October 05, 2024 | 06:00 AM

1 Hours every day

1 Days

Why people choose EveryEng

Industry-aligned courses, expert training, hands-on learning, recognized certifications, and job opportunities—all in a flexible and supportive environment.

- Industry Veteran

- Trainer Review

COMPLETED

October 5, 2024

Questions and Answers

A: Environmental considerations are critical as drilling fluids can contain chemicals harmful to ecosystems if improperly managed. Disposal of used fluids must comply with regulations to prevent soil and water contamination. Water-based fluids are generally more environmentally friendly, but additives must still be evaluated for toxicity. Oil-based and synthetic-based muds require careful handling and treatment before disposal or recycling. There is ongoing development of 'green' drilling fluids that minimize environmental impact. Regulatory guidelines, like those from the Environmental Protection Agency (EPA), offer frameworks for managing these issues responsibly.

A: Common challenges include managing the rheological properties of fluids to optimize cuttings transport, controlling fluid loss into the formation, avoiding chemical incompatibilities that may damage the formation or equipment, and environmental concerns due to disposal or spillage of hazardous fluids. Additionally, adapting fluid formulations to varying geological conditions and high-temperature, high-pressure wells adds complexity. Technological advancements continue to address these challenges by developing more robust and environmentally friendly drilling fluids. The SPE Technical Paper database is a valuable source for up-to-date research on these topics.

A: Drilling fluids maintain wellbore stability primarily through hydrostatic pressure exerted by the fluid column. By balancing the formation pore pressure, they prevent the collapse or influx of formation fluids into the wellbore. Additionally, certain additives in the fluid help form filter cakes on the wellbore walls, reducing fluid loss into formations and minimizing damage. Proper selection and maintenance of drilling fluid properties such as density, viscosity, and filtration characteristics are vital for stabilizing the wellbore. Detailed mechanisms are described in resources like "Applied Drilling Engineering" by Adam T. Bourgoyne.

A: Drilling fluid, commonly known as drilling mud, is a specially formulated liquid or slurry used in the process of drilling boreholes into the earth. Its primary functions include cooling and lubricating the drill bit, carrying drill cuttings to the surface, maintaining hydrostatic pressure to prevent formation fluids from entering the wellbore, and stabilizing the wellbore walls. Without drilling fluids, efficient and safe drilling operations would be challenging as wellbore stability and pressure control are critical to prevent blowouts and equipment damage. For more detailed information, you can refer to Society of Petroleum Engineers' resources or the Schlumberger Oilfield Glossary.

A: The main types of drilling fluids include water-based muds (WBM), oil-based muds (OBM), and synthetic-based muds (SBM). Water-based muds use water as the continuous phase and are commonly used due to their low cost and environmental acceptability. Oil-based muds use oil as the continuous phase, providing excellent lubricity and thermal stability, suitable for challenging formations. Synthetic-based muds are similar to oil-based but use synthetic oils which offer environmental advantages. Each type is selected based on well conditions, environmental regulations, and cost considerations. More insights can be found at the IADC Drilling Manual.

A: Drilling fluid technology has evolved significantly, incorporating advances such as nanotechnology additives to improve fluid properties, development of biodegradable and less toxic components, enhanced numerical modeling to predict fluid behavior, and real-time monitoring systems for better fluid management. These innovations aim to increase drilling efficiency, reduce environmental impact, and improve safety. Industry collaborations and research continue to drive these advancements. For a comprehensive overview, the latest publications from industry conferences like the IADC Annual Drilling Conference provide valuable insights.

More from Same Author

- Technical Courses

- Articles

Watch to learn anytime

1923

2

E-Learning

Unlimited access

Instructor led live training

852

Online

Live courses

Instructor led live training

606

1

Online

Live courses

Earning and Growth option in same Industry Domain

- Pre-recorded

- Online live session

- Offline

- Articles

Watch to learn anytime

1924

2

E-Learning

Unlimited access

Watch to learn anytime

7508

387

E-Learning

Unlimited access

Watch to learn anytime

4126

6

E-Learning

Unlimited access

More Training & Development option to expand your reach

- Technical courses

- Soft-skill courses

- Seminars & Conferences

- Articles & Blogs

Instructor led live training

2524

Online

Live courses

October 13

15 Hrs

Advanced

Instructor led live training

397

Online

Live courses

October 13

15 Hrs

Advanced

Instructor led live training

59

Online

Live courses

November 16

30 Hrs

Advanced