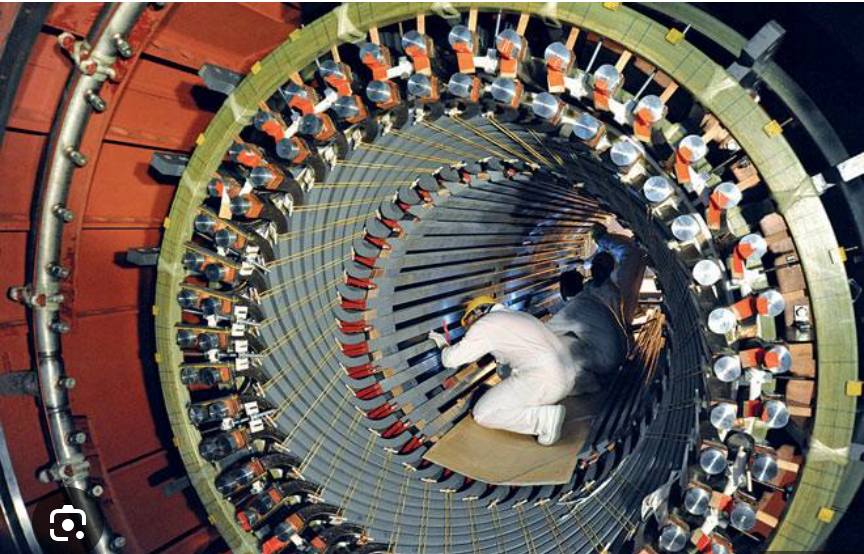

A: Regular maintenance of a power plant generator is crucial to ensure efficiency and longevity. It involves routine inspections such as checking insulation resistance, bearing conditions, cooling systems, and excitation systems. Preventive maintenance includes cleaning, lubrication, tightening electrical connections, and testing winding resistance. Periodic overhauls may require disassembling the rotor and stator for detailed inspection and repair of any wear and tear. Condition monitoring techniques like vibration analysis, thermography, and partial discharge testing are also employed to detect early signs of faults. Standards and best practices can be found in IEEE Std 762 and various manufacturer manuals. For detailed guidance, refer to: https://www.ge.com/power/services/maintenance-and-reliability-equipment-maintenance