Business Excellence through Quality, QMS & TQM

Vijay Sachdev

Consultant - Project & Procurement

COMPLETED

1 already enrolled!

Beginner course for learners

Business Excellence through Quality, QMS & TQM

Trainers feedback

0

(0 reviews)

Vijay Sachdev

Consultant - Project & Procurement

Course type

Instructor led live training

Course duration

3 Hrs

Course start date & time

January 4, 2025 | 05:30 AM

Language

English , Hindi

This course format is where trainer will explain you the subject via online live session. This course will run as per specific date and time.

Why enroll

We all are working in a "Business" domain. Prime objective of any business is to earn profit ethically / legally. But "No Customer" means "No Sale" that means "No Business". And every customer wants best Quality at lowest price. How to do it?

To achieve the Business Excellence, Quality Management Systems must be in place and effectively implemented across the Organisaiton at all levels. This can be termed as Total Quality Management (TQM) - EFQM Model. How to achieve Business Excellence will be explained during the training session,

ISO-9001 which talks about Quality Management Systems. Many organisations have obtained ISO-9001 Accreditation (just because, top management has decided to go for ISO-9001). Only very few Organisation could get the benefits / improvement after they implemnted ISO-9001.

Rest assured, your understanding and perception of Quality and Total Quality Management will change. You can learn, how to implement ISO-9001 effectively across the organisation to get the tangible and intangible gains.

Course details

Objective of this course is to train young Engineers to understand the terms "Quality" & "Quality Improvement" and to understand, "Quality is not costly". Sr Executives and Management can learn, how to bring Quality Improvement Culture in the Organisation, so as to uplift the Organisation to World Class Level.

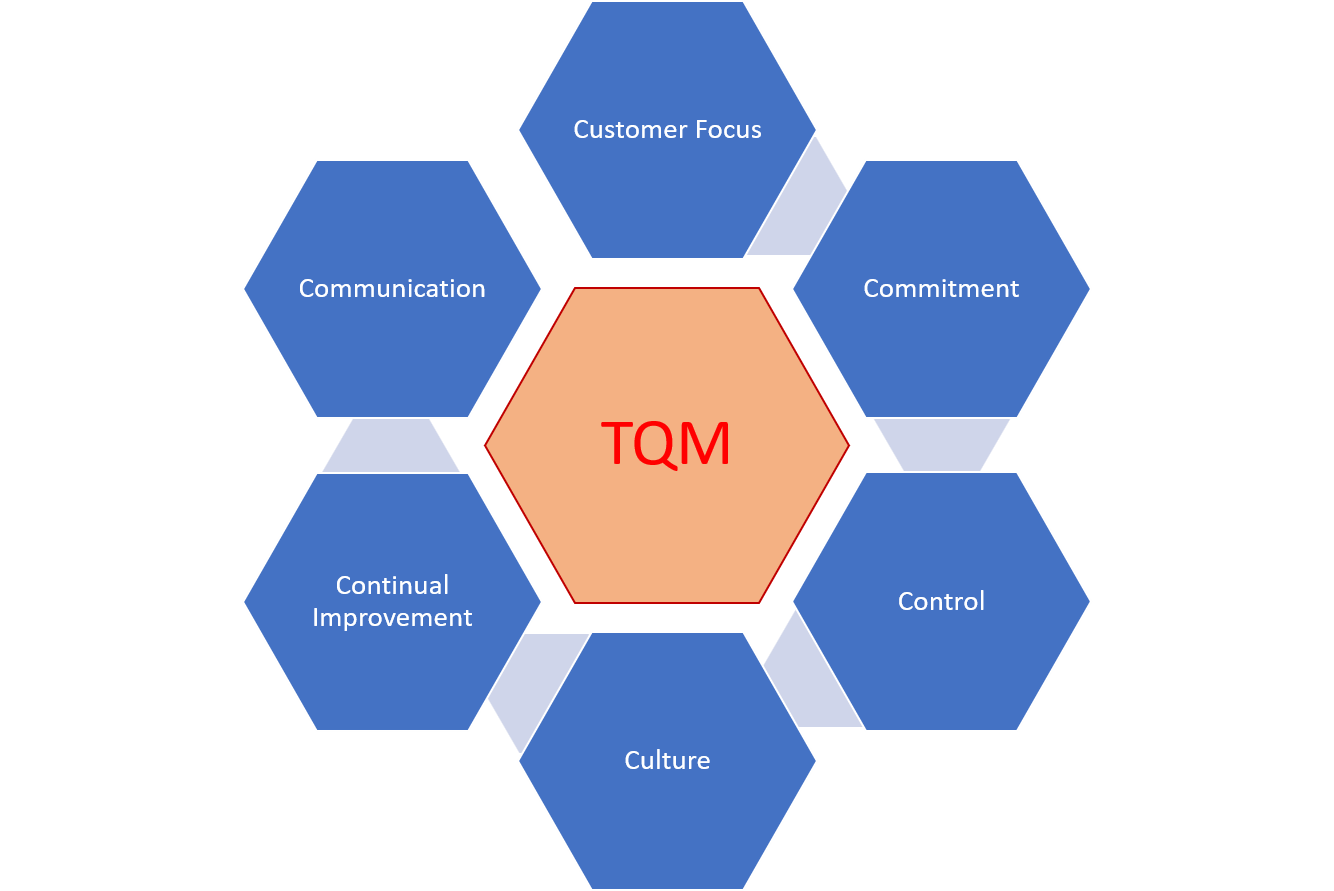

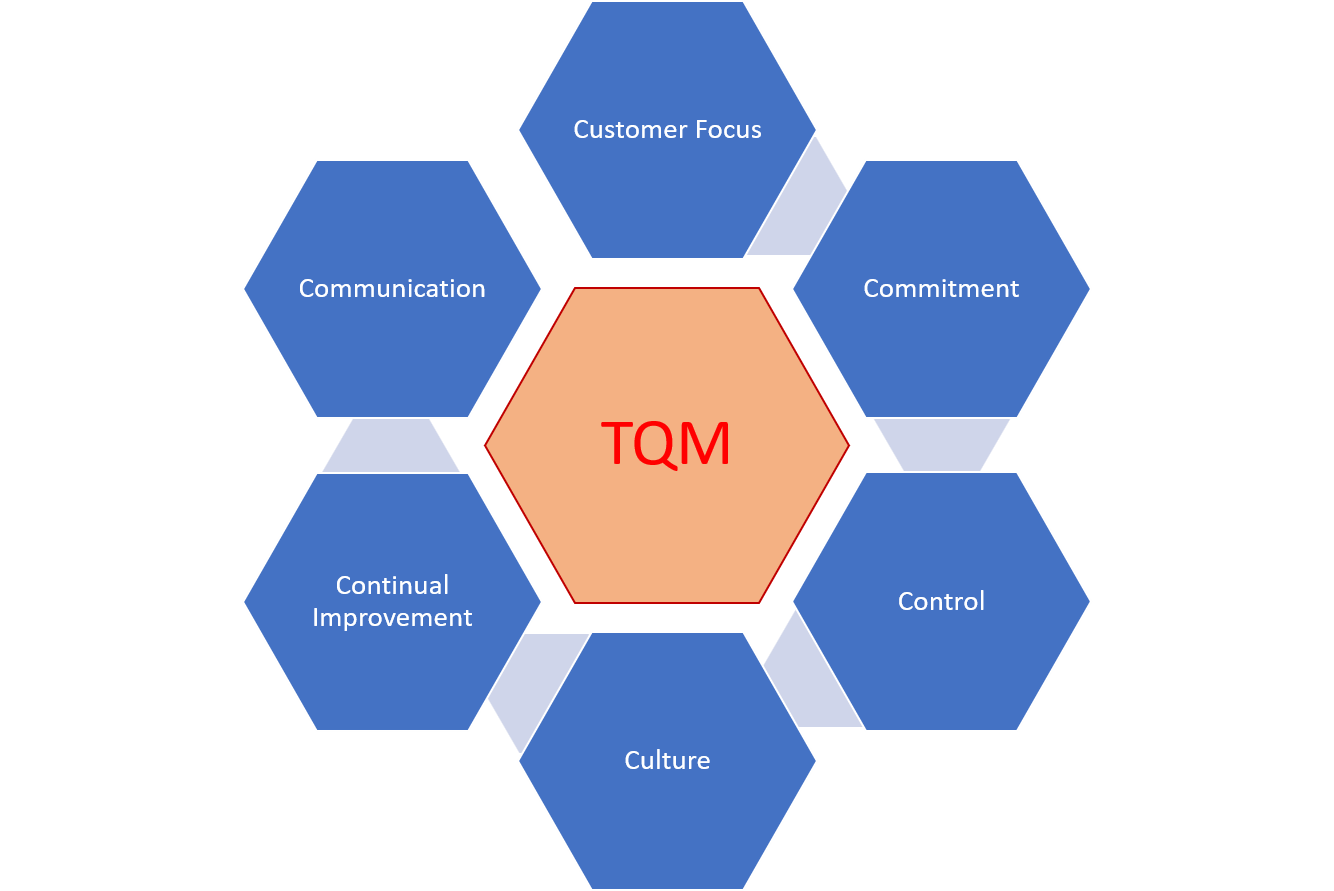

Aim of "Total Quality Management" means to bring a Culture for Business Excellence and growth of the Organisation in the Competitive Environment. As Quality is not limited to Preventing Defects. Quality Management Systems must be established and effectively implemented across the whole Organisation, so that there is no mistake, defect, non-conformity, deficiency, accidents, delay, communication gap, in any of the activity or process of the Organisation.

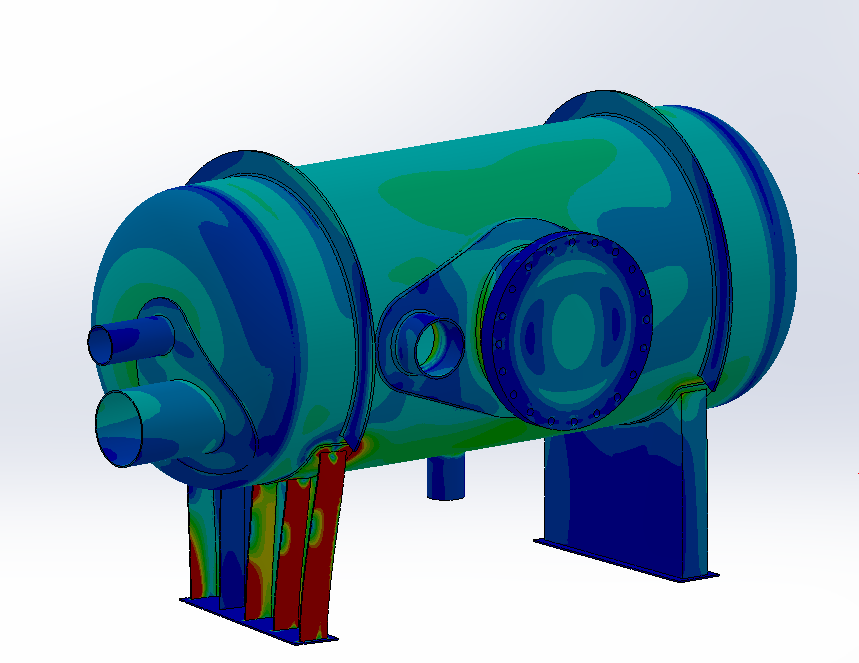

Training will be purely based on practical example and sharing experience of Manufacturing Plants of Heavy Machineries, Precision work of Power Plants, Effecitve Implemenation of Quality Management Systems and Quality Culture across the Organisation. All your questions will be answered to your satisfaction and understanding.

Course suitable for

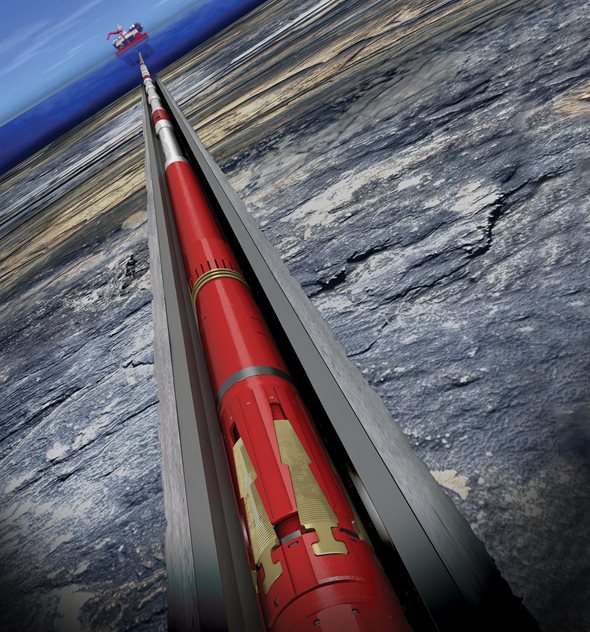

Oil & Gas Energy & Utilities Mechanics & Turbomachinery Electrical Mechanical Production

Key topics covered

Training details

This is a live course that has a scheduled start date.

Live session

January 04, 2025 | 05:30 AM

3 Hours every day

1 Days

Why people choose EveryEng

Industry-aligned courses, expert training, hands-on learning, recognized certifications, and job opportunities—all in a flexible and supportive environment.

- Industry Veteran

- Trainer Review

COMPLETED

January 4, 2025

Questions and Answers

A: Risk-based thinking is an approach that involves identifying, assessing, and mitigating risks that could impact product quality, customer satisfaction, or regulatory compliance. In Quality Management Systems, especially ISO 9001:2015, risk-based thinking replaces solely prescriptive procedures to enhance process reliability and effectiveness. It encourages proactive measures rather than reactive fixes, improving decision-making and resource prioritization. Incorporating risk management helps organizations prevent failures, capitalize on opportunities, and increase resilience. More information is available at: https://asq.org/quality-resources/risk-management

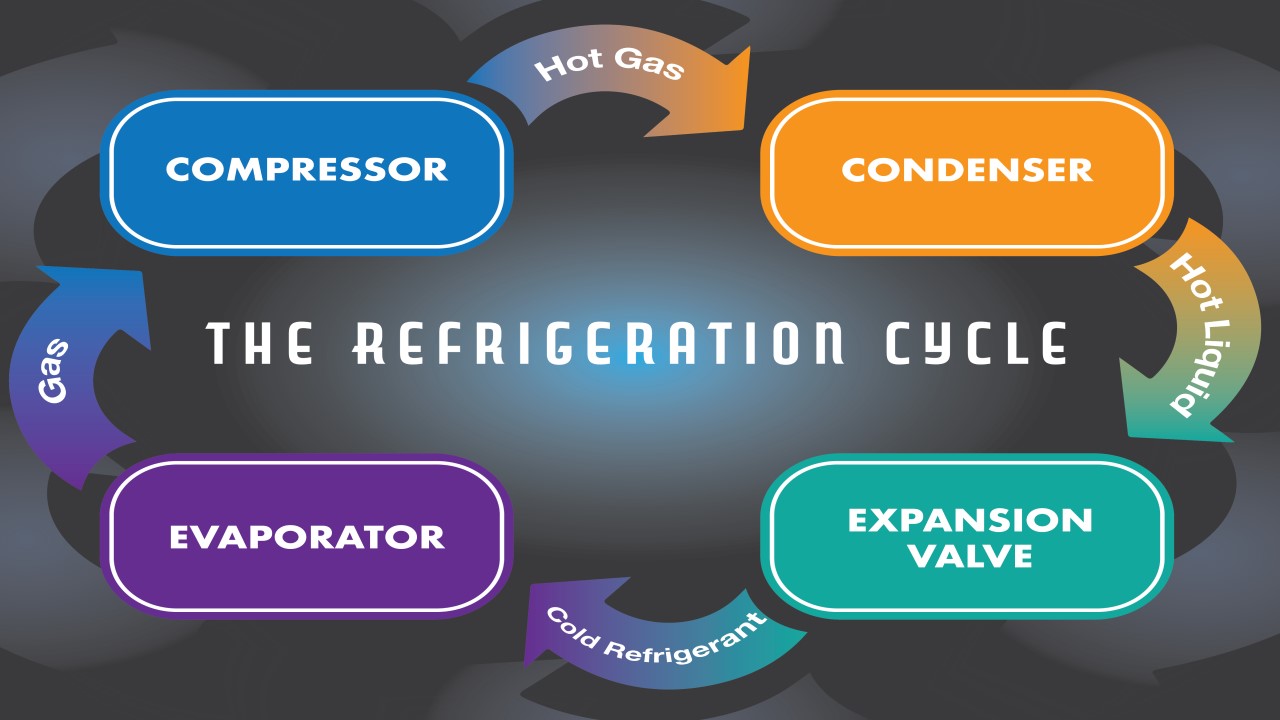

A: Six Sigma is a data-driven methodology focused on reducing defects and variability in processes using statistical tools. Within the broader framework of Total Quality Management (TQM), Six Sigma can be seen as a complementary approach that provides rigorous techniques to address quality problems. TQM promotes a culture of continuous improvement and customer focus, while Six Sigma delivers a structured, project-driven roadmap (DMAIC – Define, Measure, Analyze, Improve, Control) to achieve measurable gains. Organizations often integrate Six Sigma projects as part of their TQM initiatives to enhance process capability and quality.

A: Customer focus is central to achieving business excellence because customer satisfaction drives loyalty, market share, and profitability. Business excellence models emphasize understanding and meeting customer needs and expectations consistently. By prioritizing customer requirements, organizations can tailor processes, innovate effectively, and differentiate from competitors. Incorporating customer feedback into product and service improvements enables continuous alignment with market demands. The EFQM model and ISO 9001 both underscore customer focus as a foundational principle. For further reading: https://asq.org/quality-resources/customer-focus

A: ISO 9001 is an internationally recognized standard that provides a framework for establishing, implementing, maintaining, and continually improving a quality management system (QMS). It helps organizations consistently meet customer and regulatory requirements while enhancing customer satisfaction. The standard emphasizes process approach, risk-based thinking, leadership involvement, and continuous improvement. By complying with ISO 9001, organizations can standardize processes, improve efficiency, reduce errors, and strengthen customer confidence. You can learn more at the official ISO website: https://www.iso.org/iso-9001-quality-management.html

A: Business Excellence models like the EFQM Excellence Model are frameworks designed to help organizations assess and improve their performance systematically. The EFQM model is based on nine criteria divided into 'Enablers' (Leadership, Strategy, People, Partnerships & Resources, Processes, Products & Services) and 'Results' (Customer Results, People Results, Society Results, and Business Results). The key principles include customer focus, leadership, engagement of people, process approach, continuous improvement, evidence-based decision making, and relationship management. The model assists organizations in aligning initiatives and measuring maturity towards excellence. More information can be found here: https://www.efqm.org/

A: Organizations can measure the success of their Quality Management System (QMS) through various metrics like customer satisfaction scores, process efficiency indicators, defect or error rates, audit results, and compliance with standards such as ISO 9001. Key Performance Indicators (KPIs) should be aligned with organizational goals and continuously monitored. Also, internal and external audits provide insights into QMS effectiveness. The ultimate measure is the ability to consistently meet customer needs, reduce costs related to poor quality, and achieve continuous improvement. Using balanced scorecards and maturity models can also provide a broader perspective on success.

A: Leadership plays a pivotal role in fostering an organizational culture that values quality and business excellence. Effective leaders set a clear vision, communicate quality objectives, allocate resources, and motivate employees to engage in quality initiatives. They demonstrate commitment through their actions, promote accountability, and facilitate continuous improvement. Leadership engagement also ensures alignment of strategies with customer needs and regulatory demands. Without strong leadership, quality programs may lack direction and sustainability. The importance of leadership in quality management is highlighted in frameworks such as ISO 9001 and EFQM. For more insights, see: https://asq.org/quality-resources/leadership

A: Common challenges in QMS implementation include resistance to change, lack of leadership commitment, inadequate training, poor communication, and insufficient resource allocation. Organizations may also struggle with process documentation and integration of quality into daily operations. To overcome these challenges, companies should secure strong top management support, provide adequate training, involve employees at all levels, communicate benefits clearly, and deploy continuous improvement practices. Engaging change management techniques and using pilot projects before full rollout can also aid success.

A: Total Quality Management (TQM) is a management approach focused on long-term success through customer satisfaction. It involves all members of an organization in improving processes, products, services, and culture continuously. Unlike traditional quality control, which typically focuses on detecting defects after production, TQM emphasizes prevention of defects through proactive quality improvement at every stage. TQM integrates quality into every organizational process rather than isolating it in a separate department. For more details, see: https://asq.org/quality-resources/total-quality-management

A: Continuous improvement, often called 'Kaizen', is an ongoing effort to enhance products, services, or processes incrementally over time. It promotes small, consistent changes rather than large-scale transformations. The Plan-Do-Check-Act (PDCA) cycle is a core tool used to structure these improvements. The cycle involves four stages: Plan (identify a problem and develop a plan), Do (implement the plan on a small scale), Check (evaluate results and analyze data), and Act (standardize the successful improvement or begin another cycle). This iterative process helps organizations embed a culture of quality and adaptability. More on PDCA here: https://asq.org/quality-resources/pdca-cycle

More from Same Author

- Technical Courses

- Articles

Instructor led live training

1011

25

Online

Live courses

December 15

1 Hrs

35

Watch to learn anytime

3781

2

E-Learning

Unlimited access

Instructor led live training

861

1

Online

Live courses

January 4

3 Hrs

Earning and Growth option in same Industry Domain

- Pre-recorded

- Online live session

- Offline

- Articles

35

Watch to learn anytime

3781

2

E-Learning

Unlimited access

28

Watch to learn anytime

4876

82

E-Learning

Unlimited access

Md Firan Mondal

Lead HVAC Engineer | CEng, MIMechE, UK I CEng, KIVI, Europe I B.E (Mechanical) I Oil & Gas I HVAC Wind Platforms I Green Hydrogen I Blogger

$10

Watch to learn anytime

315

1

E-Learning

Unlimited access

More Training & Development option to expand your reach

- Technical courses

- Soft-skill courses

- Seminars & Conferences

- Articles & Blogs

Instructor led live training

634

1

Online

Live courses

September 29

9 Hrs

Beginner

Instructor led live training

465

1

Online

Live courses

October 11

14 Hrs

Advanced

Instructor led live training

578

Online

Live courses

October 11

4 Hrs

Intermediate