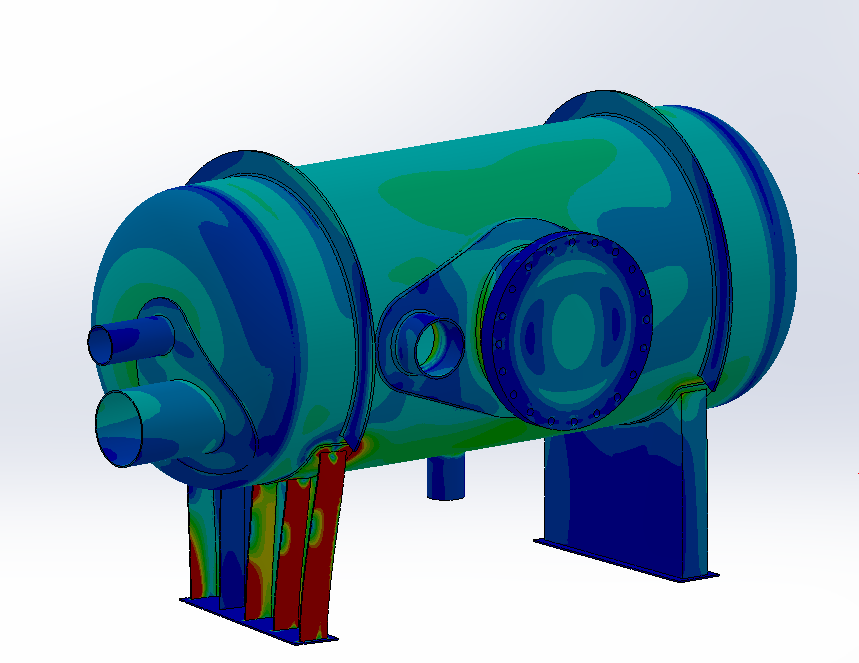

Finite Element Analysis (FEA) Fundamentals and ASME Section VIII Division 2 Part 5 Implementation for Pressure Vessel Design

Anindya Bhattacharya

Asset Engineer

COMPLETED

3 already enrolled!

Advanced course for professionals

Finite Element Analysis (FEA) Fundamentals and ASME Section VIII Division 2 Part 5 Implementation for Pressure Vessel Design

Trainers feedback

0

(0 reviews)

Anindya Bhattacharya

Asset Engineer

Course type

Instructor led live training

Course duration

14 Hrs

Course start date & time

October 11, 2025 | 08:01 AM

Language

English

This course format is where trainer will explain you the subject via online live session. This course will run as per specific date and time.

Training details

This is a live course that has a scheduled start date.

Live session

October 11, 2025 | 08:01 AM

2.8 Hours every day

5 Days

Why people choose EveryEng

Industry-aligned courses, expert training, hands-on learning, recognized certifications, and job opportunities—all in a flexible and supportive environment.

- Industry Veteran

- Trainer Review

COMPLETED

October 11, 2025

Questions and Answers

A: Common challenges include modeling complex geometries, achieving mesh convergence, defining realistic loads and boundary conditions, and interpreting stress results within code limits. Additionally, ensuring material property accuracy and validating the model against experimental or analytical solutions are vital. These challenges can be addressed through thorough training, use of proven software tools, applying mesh refinement strategies, performing sensitivity analyses, and adhering strictly to ASME Sec VIII Div 2 Part 5 guidelines. Peer reviews and quality assurance processes also enhance the reliability of FEA implementations.

A: Fatigue analysis is essential for pressure vessels subjected to cyclic loading. ASME Sec VIII Div 2 Part 5 incorporates fatigue design rules that require assessment of stresses over repeated load cycles to prevent crack initiation and propagation. FEA helps calculate stress ranges and identify critical areas prone to fatigue damage. The code provides allowable stress ranges and cumulative usage factors to evaluate service life. Integration of fatigue with FEA includes applying appropriate load spectra, assessing secondary and peak stresses, and using cycle counting methods. Consult the ASME BPVC Fatigue Design and Analysis section along with FEA results to ensure compliance.

A: Boundary conditions simulate constraints and interactions between the pressure vessel and its environment or support structures in an FEA model. Accurately defining these conditions is vital because they influence stress distribution and deformation results. ASME Sec VIII Div 2 Part 5 requires that boundary conditions reflect realistic physical restraints such as fixed supports, symmetry, and load transfers to adjacent components. Incorrect or oversimplified boundary conditions may produce inaccurate results and non-conservative designs. Proper documentation and justification of boundary conditions are also required for code compliance.

A: Key material properties required include the elastic modulus (Young's modulus), Poisson's ratio, yield strength, ultimate tensile strength, and allowable stress values specific to the material used in the pressure vessel. Time-dependent properties like creep or fatigue characteristics may also be relevant, depending on operating conditions. These properties must be derived from certified material data and consistent with the ASME code requirements to ensure the integrity and safety of the pressure vessel under applied loads. For detailed material property requirements, see ASME Sec VIII Div 2 Part 5 and relevant material specifications such as ASTM standards.

A: The loads usually considered include internal and external pressure, dead weight, thermal expansion, seismic loads, wind loads, and any operational loads such as nozzle forces and moments. The ASME code specifies load combinations that must be analyzed to ensure safety under all plausible scenarios. Additionally, dynamic effects or cyclic loading might be examined depending on the vessel's service conditions. Properly defining these loads per code requirements and applying them correctly in the FEA is essential to comply with ASME Sec VIII Div 2 Part 5.

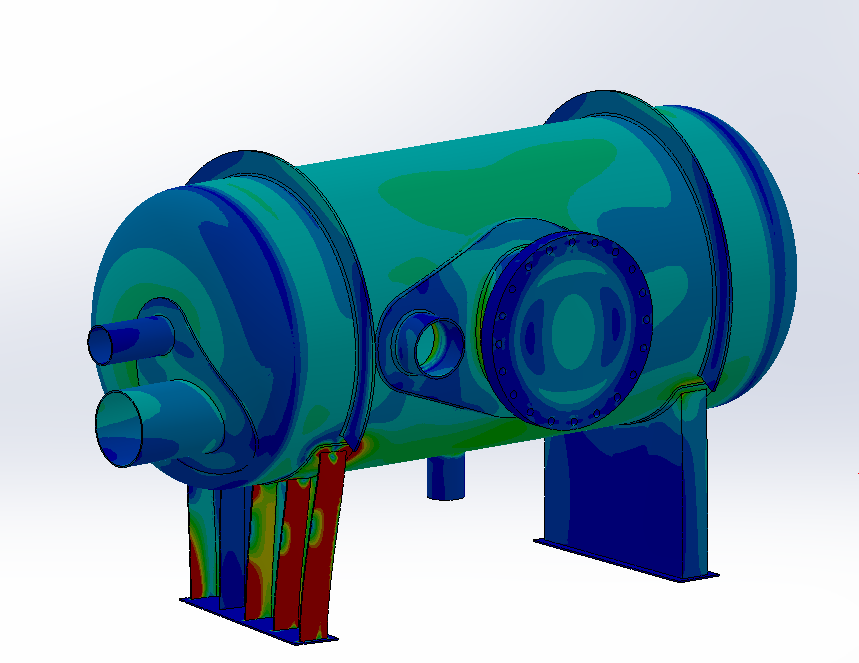

A: Finite Element Analysis (FEA) is a numerical method used to solve complex engineering and physical problems. It involves breaking down a large system into smaller, simpler parts called finite elements. These elements are interconnected at points called nodes. By applying equations that govern physical laws, FEA calculates how each element behaves under various conditions such as stress, heat, or vibration. The collective behavior of these elements gives an approximate solution to the entire problem. For an introduction, you might refer to the "Introduction to Finite Element Analysis" section on [NASA's FEA resources](https://www.grc.nasa.gov/WWW/Structures/FEA.html).

A: Acceptance criteria in ASME Sec VIII Div 2 Part 5 are based on stress limits derived from allowable stresses and defined stress categories such as primary, secondary, and peak stresses. The code requires that calculated stresses do not exceed these limits to avoid plastic deformation or fatigue failure. For example, primary membrane stresses must remain within allowable stress to ensure structural integrity, while fatigue checks apply to secondary and peak stresses. The part also outlines safety factors and recommended evaluation procedures. Detailed criteria can be found in the code itself, which should be reviewed carefully during the design and verification stages.

A: Mesh quality and refinement are critical in FEA to obtain accurate and reliable results. ASME Sec VIII Div 2 Part 5 stresses the need for an adequately refined mesh, particularly in regions of high stress gradients such as nozzles, welds, or geometric discontinuities. Poor mesh quality can lead to inaccurate stress predictions, convergence issues, or unsafe designs. Techniques such as mesh convergence studies, using appropriate element types, ensuring aspect ratio within acceptable limits, and applying local refinement where necessary are recommended best practices. More detailed guidance can be found in specialized FEA textbooks like "The Finite Element Method" by O.C. Zienkiewicz and code-related application notes.

A: ASME Boiler and Pressure Vessel Code Section VIII Division 2 Part 5 provides detailed rules and requirements for performing Finite Element Analysis on pressure vessels. It establishes the design criteria, allowable stresses, and validation procedures needed to ensure safety and compliance when using FEA as part of the design or assessment process. This section emphasizes the importance of mesh quality, boundary conditions, load applications, and documentation to produce reliable and verifiable results. More information on these requirements can be found in the official ASME Boiler and Pressure Vessel Code documentation or summarized in various engineering standards resources such as [ASME's website](https://www.asme.org/codes-standards).

A: Several commercial FEA software packages such as ANSYS, Abaqus, and Siemens NX have capabilities to perform analyses compliant with ASME Sec VIII Div 2 Part 5 requirements. These tools offer specialized modules for pressure vessel design, including predefined material libraries, load cases, and automated report generation aligned with code standards. However, compliance depends on the user's expertise and correct application of the tools in accordance with the code. It's crucial to validate the software setup for specific projects and maintain documentation demonstrating ASME conformance. For further details on software compliance, consult vendor documentation and ASME guidelines.

More from Same Author

- Technical Courses

- Articles

37

Watch to learn anytime

1412

8

E-Learning

Unlimited access

Instructor led live training

1155

Online

Live courses

Instructor led live training

908

Online

Live courses

Earning and Growth option in same Industry Domain

- Pre-recorded

- Online live session

- Offline

- Articles

35

Watch to learn anytime

3781

2

E-Learning

Unlimited access

28

Watch to learn anytime

4876

82

E-Learning

Unlimited access

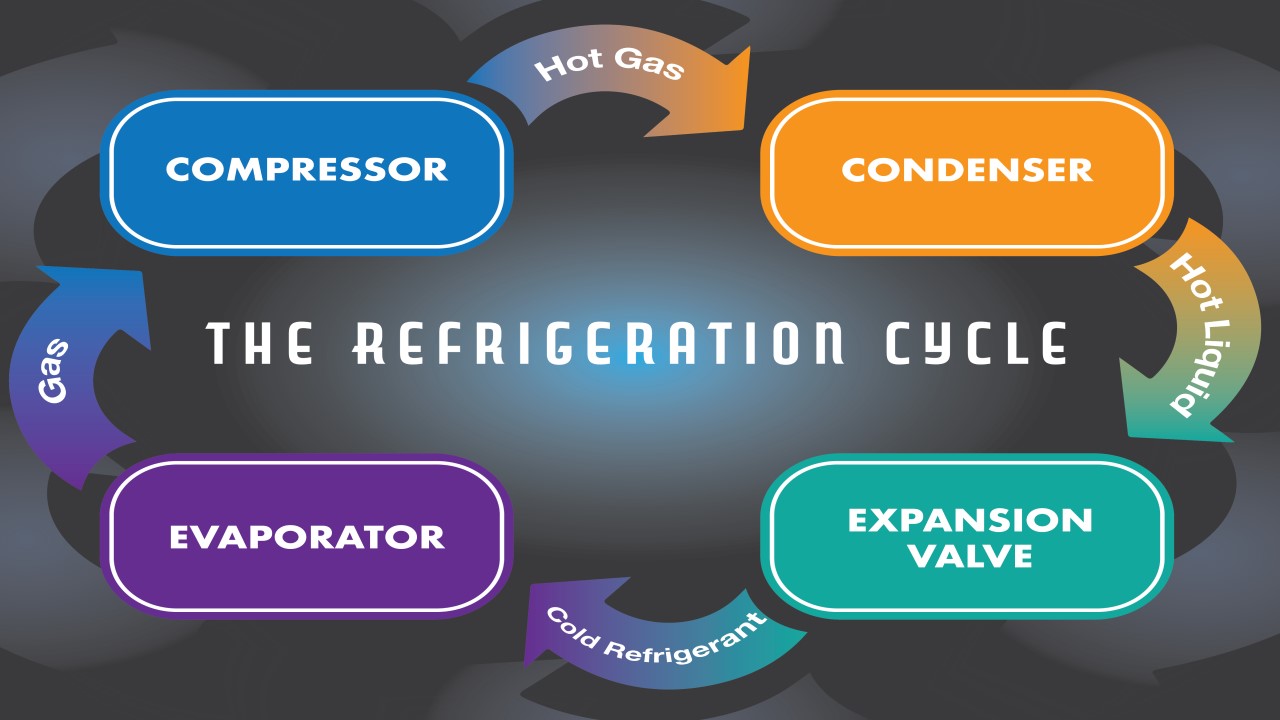

Md Firan Mondal

Lead HVAC Engineer | CEng, MIMechE, UK I CEng, KIVI, Europe I B.E (Mechanical) I Oil & Gas I HVAC Wind Platforms I Green Hydrogen I Blogger

$10

Watch to learn anytime

315

1

E-Learning

Unlimited access

More Training & Development option to expand your reach

- Technical courses

- Soft-skill courses

- Seminars & Conferences

- Articles & Blogs

Instructor led live training

634

1

Online

Live courses

September 29

9 Hrs

Beginner

Instructor led live training

465

1

Online

Live courses

October 11

14 Hrs

Advanced

Instructor led live training

578

Online

Live courses

October 11

4 Hrs

Intermediate